Caracteristici:

1. The front–feeding platform has equipped with ruler for the plate feeding and also smooth in the surface to protect the plate in any surface hurting when feeding. The ruler can be precision into MM or more unit for accuracy control and checking.

2. The working table has equipped with ball or round bar steel to support the plate into feeding and also the protection for any surface lacerate.

3. The electronic box been equipped with good certificated components.Mostly we use CE certificated SIEMENS or Schneider components for exportation machines and also some high quality CCC certificated components to carte for different standard needs clients.

4. The machine body steel ,we mostly choose China top brand steel plate provider Shanghai BAOSTEEL with good quality and been treated with anticorrosive paint before the last paint on. So the machine firstly will have good durable usage and also perfect outside appearance.

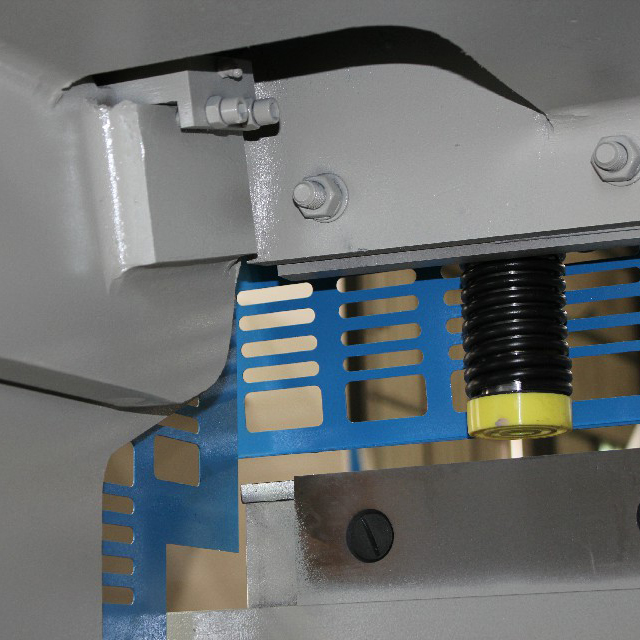

5. The blade: The blade material is 9CrSi or 6CrW2Si, the material is high tested material with thousand times for high rigidity and cutting result. The up blade is rectangle blade with four blade edges which is different from QC12Y Swing Beam shear machine (The detailed please check SIECC/SIECCTECH blade explain photo and instruction). The blade clearance can be adjusted by manual or by motor. Both has the index dial to display the clearance so the control and display can be easily. And the up blade shaft use tilting structure to promote the shearing precision.

6. The machine equipped the press foot to press the plate stably when cutting, the foot has been equipped with plastic surface with high fraction without surface destroy of the plate. For Hole plate,we will equip square foot for stable square press.

7. Gear Pump: We use good brand “straight conjugate internal gear pump” in both China brand Shanghai chengjie or Germany Eckerler. The internal gear pump is treated as never wear pump in industry and has been widely used in high precision hydraulic machines with the character of low-noise, no pulsation and long lifetime. Shanghai Chengjie gear pump also used in China’s aircraft industry so it is trustable and reliable. When in high speed working, the audio is flat and smooth even no trapping. The long lifetime is depend on his abrasive performance the inner machine components has oil film protection layer, so even use normal hydraulic oil, even no abrasion.

8. The hydraulic system can use Germany Rexroth or USA OMG system. The return is controlled by nitrogen return cylinder with stable working process and easy in operation. The hydraulic press enforced up transmission and nitrogen impose the up push-out with good cooperation working. (The working principle can revert to SIECC technology drawing of QC11Y and QC12Y)

9. Backgauge are counted by counter and can be micro-adjusted and is motor drived.

10. The machine will be equipped with fence protection door before the cutting blade and the press foot. The fence can be opened if any needed. Near the throat, we will equipped with open-available door for person security but open-able when needs any inside checking.

11. Using three bearing rolling track to eliminate rail gap and enhance the shearing quality. (Machine drawing available for

clearly explain)

Specificație

| Model | Max.Thickness | Yield strength | Max. Length | Unghi | X.Stroke | Frecvență | Putere | L*W*H (mm) | Greutate |

| QC12Y-4*2500 | 4mm | ≤450kN/cm | 2500 mm | 1°30' | 20~600mm | 16Times/min | 5.5kW | 3040*1610*1620 | 3800Kg |

| QC12Y-4*3200 | 4mm | ≤450kN/cm | 3200 mm | 1°30' | 20~600mm | 14Times/min | 5.5kW | 3840*1610*1620 | 5000Kg |

| QC12Y-4*4000 | 4mm | ≤450kN/cm | 4000 mm | 1°30' | 20~600mm | 10Times/min | 5.5kW | 4600*1700*1700 | 6500Kg |

| QC12Y-4*6000 | 4mm | ≤450kN/cm | 6000 mm | 1°30' | 20~600mm | 8Times/min | 7,5 kW | 6460*2100*3200 | 11000Kg |

| QC12Y-6*2500 | 6 mm | ≤450kN/cm | 2500 mm | 1°30' | 20~600mm | 14Times/min | 7,5 kW | 3040*1610*1620 | 5000Kg |

| QC12Y-6*3200 | 6 mm | ≤450kN/cm | 3200 mm | 1°30' | 20~600mm | 12Times/min | 7,5 kW | 3840*1610*1620 | 6000Kg |

| QC12Y-6*4000 | 6 mm | ≤450kN/cm | 4000 mm | 1°30' | 20~600mm | 8Times/min | 7,5 kW | 4620*1750*1700 | 8200Kg |

| QC12Y-6*5000 | 6 mm | ≤450kN/cm | 5000 mm | 1°30' | 20~600mm | 6Times/min | 11 kW | 5400*1800*1900 | 10500Kg |

| QC12Y-6*6000 | 6 mm | ≤450kN/cm | 6000 mm | 1°30' | 20~600mm | 5Times/min | 11 kW | 6480*2100*2300 | 16500Kg |

| QC12Y-8*2500 | 8 mm | ≤450kN/cm | 2500 mm | 1°30' | 20~600mm | 10Times/min | 11 kW | 3040*1700*1700 | 6000Kg |

| QC12Y-8*3200 | 8 mm | ≤450kN/cm | 3200 mm | 1°30' | 20~600mm | 8Times/min | 11 kW | 3860*1700*1700 | 7200Kg |

| QC12Y-8*4000 | 8 mm | ≤450kN/cm | 4000 mm | 1°30' | 20~600mm | 8Times/min | 11 kW | 4640*1700*1700 | 8800Kg |

| QC12Y-8*5000 | 8 mm | ≤450kN/cm | 5000 mm | 1°30' | 20~600mm | 8Times/min | 11 kW | 5400*2100*2000 | 11500Kg |

| QC12Y-8*6000 | 8 mm | ≤450kN/cm | 6000 mm | 1°30' | 20~600mm | 8Times/min | 11 kW | 6480*2100*2350 | 18000Kg |

| QC12Y-10*2500 | 10 mm | ≤450kN/cm | 2500 mm | 2° | 20~600mm | 9Times/min | 11 kW | 3040*1700*1700 | 7300Kg |

| QC12Y-10*3200 | 10 mm | ≤450kN/cm | 3200 mm | 2° | 20~600mm | 9Times/min | 11 kW | 3860*1700*1700 | 8000Kg |

| QC12Y-10*4000 | 10 mm | ≤450kN/cm | 4000 mm | 2° | 20~600mm | 8Times/min | 11 kW | 4650*2100*2000 | 12050Kg |

| QC12Y-10*6000 | 10 mm | ≤450kN/cm | 6000 mm | 2° | 20~1000mm | 5Times/min | 15KW | 6500*2100*2300 | 24000Kg |

| QC12Y-12*2500 | 12 mm | ≤450kN/cm | 2500 mm | 1°40' | 20~600mm | 9Times/min | 18.5KW | 3140*2150*2000 | 9000Kg |

| QC12Y-12*3200 | 12 mm | ≤450kN/cm | 3200 mm | 1°40' | 20~600mm | 9Times/min | 18.5KW | 3880*2150*2000 | 10800Kg |

| QC12Y-12*4000 | 12 mm | ≤450kN/cm | 4000 mm | 1°40' | 20~1000mm | 8Times/min | 18.5KW | 4680*2150*2000 | 13000Kg |

| QC12Y-12*5000 | 12 mm | ≤450kN/cm | 5000 mm | 2° | 20~1000mm | 6Times/min | 18.5KW | 5900*2150*2000 | 16000Kg |

| QC12Y-12*6000 | 12 mm | ≤450kN/cm | 6000 mm | 2° | 20~1000mm | 5Times/min | 18.5KW | 6900*2600*2700 | 29500Kg |

| QC12Y-12*8000 | 12 mm | ≤450kN/cm | 8000mm | 2° | 20~1000mm | 5Times/min | 18.5KW | 9000*3500*3500 | 46500Kg |

| QC12Y-16*2500 | 16mm | ≤450kN/cm | 2500 mm | 2°30' | 20~600mm | 9Times/min | 22 kW | 3140*2150*2000 | 11000Kg |

| QC12Y-16*3200 | 16mm | ≤450kN/cm | 3200 mm | 2°30' | 20~600mm | 8Times/min | 22 kW | 388 0*2150*2000 | 13000Kg |

| QC12Y-16*4000 | 16mm | ≤450kN/cm | 4000 mm | 2°30' | 20~1000mm | 8Times/min | 22 kW | 4650*2150*2200 | 16300Kg |

| QC12Y-16*5000 | 16mm | ≤450kN/cm | 5000 mm | 2°30' | 20~1000mm | 6Times/min | 22 kW | 5900*2600*2700 | 20000Kg |

| QC12Y-16*6000 | 16mm | ≤450kN/cm | 6000 mm | 2°30' | 20~1000mm | 5Times/min | 22 kW | 6900*2700*2700 | 36000Kg |

| QC12Y-16*8000 | 16mm | ≤450kN/cm | 8000mm | 2°30' | 20~1000mm | 5Times/min | 22 kW | 9000*3500*3500 | 75000Kg |

| QC12Y-20*2500 | 20mm | ≤450kN/cm | 2500 mm | 3° | 20~1000mm | 8Times/min | 22 kW | 3440*2300*2500 | 15800Kg |

| QC12Y-20*3200 | 20mm | ≤450kN/cm | 3200 mm | 3° | 20~1000mm | 8Times/min | 22 kW | 4150*2350*2700 | 18500Kg |

| QC12Y-20*4000 | 20mm | ≤450kN/cm | 4000 mm | 3° | 20~1000mm | 5Times/min | 22 kW | 4850*2600*2700 | 21500Kg |

| QC12Y-20*6000 | 20mm | ≤450kN/cm | 6000 mm | 3° | 20~1000mm | 4Times/min | 30KW | 6700*3000*3000 | 47000Kg |

| QC12Y-25*2500 | 25mm | ≤450kN/cm | 2500 mm | 3° | 20~1000mm | 8Times/min | 37KW | 3200*2700*2900 | 19000Kg |

| QC12Y-25*3200 | 25mm | ≤450kN/cm | 3200 mm | 3° | 20~1000mm | 5Times/min | 37KW | 4200*2700*2900 | 23000Kg |

| QC12Y-30*2500 | 30mm | ≤450kN/cm | 2500 mm | 3° | 20~1000mm | 4Times/min | 37KW | 3300*2900*3000 | 23500Kg |

| QC12Y-30*3200 | 30mm | ≤450kN/cm | 3200 mm | 3°30' | 20~1000mm | 4Times/min | 40KW | 4200*2900*3200 | 26000Kg |

| QC12Y-40*2500 | 40mm | ≤450kN/cm | 2500 mm | 4° | 20~1000mm | 3Times/min | 55KW | 3200*3300*3000 | 38000Kg |

| QC12Y-40*3200 | 40mm | ≤450kN/cm | 2500 mm | 4° | 1000mm | 3Times/min | 55KW | 4300*3300*3200 | 49000Kg |

Detalii

PROCESUL DE FONDERE

Perfect design in every aspect; By choosing the new and improved CNC guillotine, we'll have maximumsafety, high accuracy and unique ease of use.

Blade gap, cutting angle and cutting length are all adjusted based on material selection and thickness automatically.

The critical parts of the KEC press brakes and shearing machines are manufactured in Germany.

The carefully selected components come from long-term partners globalwise.

We rely on our quality and therefore give our guillotine a 3-year warranty.

Motor principal Siemens

Using Siemens Motor guarantees the machine service life, and reduce the noise when working.

Blade Clourancant Rapid adjustment

Rapid adjustment mechanism for rearranging blade clearance.easy operation by hand. realizing stepless adjustment of blade clearance .

Regulator de verticalitate pentru poziționare frontală

Front positioning device, setting verticality and positioning device on the left-most front support, guranteeing the cutting precision, easy operation, pratical and efficient.

Banc de lucru Rolling Steel Ball

Bila de oțel de rulare a bancului de lucru poate reduce frecarea, protejează suprafața piesei de prelucrat.

Cilindru de presiune cu arc încorporat

Its lower end equipped with special material gasket, sparately control the pressure, avoiding aluminium alloy or other softer

materials being imprinted.

Ecartament spate de înaltă precizie

The unique and novel ball screw linear guide structure back-gauge ensures high positioning accuracy. Adjustable beam guiding rule and synchronous transmission structure, stable and reliable. Optional lifting mechanism structure to cut the work piece out of back gauge range. When cutting thin and wide metal plates, pneumatic support device can be selected. Increased positioning range makes cutting more efficient and accurate.

Stable Electrical Cabinet

Durable France Schneider electrics ensure the stable operation of the machine. Reasonable line connection and arrangement greatly reduces the failure rate. And the operator and all parts of the machine played a good protection. Optional Servo and drive to improve the positioning accuracy of back-guage (X)Axis.

CONFIGURARE

CNC Control System : Estun E21S Control from Nanjing

Electrical components : Schneider Electrical from French

Motor principal: marca Siemens din Germania

Angle measurement Sensor: OPKON from Türkçe Brand

Inverter Drive: Taiwan DELTA Servo Motor & Driving System

PLC: Schneider Electrical from French

Cutting Blades: Shark Toolings from China

Hydraulic System: Bosch-Rexroth from Germany

Hydraulic Pump: SUNNY from U.S.A Brand or equivalent Brand

Tubing connector: EMB Brand from Germany

Ball Screw/ Liner guide: HIWIN from TaiWan Area

Controler E21S

* Backgauge and block control

* Control for general AC motors, frequency inverter

* Poziționare inteligentă

* Contor stoc

* Setarea timpului de menținere/decompresie

* Program memory of up to 40 programs

* Up to 25 steps per program

* Poziționare pe o singură parte

* Funcția de retragere

* O singură cheie de rezervă/restaurare a parametrilor

* mm/inch

* Chinese /English

FAQ

1. Q: We see many Chinese brands there in market, are they all manufacturers? What about KEC/yaduan?

A: It is true that among all those Chinese brands, most of them are trading brands.

But KEC/yaduan is the real manufacturer that has been making hydraulic press brakes and shearing machines since 2008.

2. Q: How to get an accurate quotation from KEC ?

A: Simply provide us the details of material , max thickness and max width you would like to work with.

3. Q: Can you do OEM service ?

A: Sure. your design or other requirements are accepted , your own logo can be effected on the machine.

4. Q: What's the shipping cost from China to your country ?

A:We can send machine to your port or door address by sea.

Please kindly tell us your nearest port or address with postcode.

We work with several reliable shipping agents to arrange global shipping in multiple ways.

5. Q: What is the average lead time?

A: For stocks, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective upon deposit receipt. If our lead times do not work with your deadline, We could arrange special urgent production so to catch our deadline. In all cases we will try to accommodate your needs. In most cases we are able to manage quick delivery.

6. Q: Can you supply the relevant shipping documentation?

A: Yes, we can provide most documents including

Bill of lading;

Certificates of Analysis /Conformance;

CE certificate, COC certificate;

Insurance;

Country of Origin;

Commercial invoice;

Packing list and other export documents whatever required.

7. Q: Do you accept LC payment ?

A: Yes, normally our payment is 30% 70% T/T, LC payment is also acceptable

8. Q: How to operate the machines ordered ?

A: Videos of the machines before shipment in our factory will be sent to you directly.

9. Q: What about commissioning service ?

A: We can offer commissioning service, the buyer need to afford plane tickets.

10. Q: What is the product warranty?

A: Normally 3 years. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

11. Q: Do you guarantee safe and secure delivery of products?

A: Yes, we always use high quality export packaging. We also use specialized solid packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Special packaging and non-standard packing requirements will charge additionally.

Detalii

- Max. Latime de taiere (mm): 3200

- Max. Grosime de tăiere (mm): 12 mm

- Nivel automat: complet automat

- Shearing Angle: 1.5 degree

- Blade Length (mm): 2400 mm

- Cursa ecartamentului din spate (mm): 20 - 600 mm

- Adâncimea gâtului (mm): 150 mm

- Stare: Nou

- Putere (kW): 18,5 kW

- Weight (KG): 10800 KG

- Voltage: 380V/50HZ/3PH

- Dimension(L*W*H): 3880*2150*2000

- Anul: 2021

- Garantie: 3 ani

- Puncte cheie de vânzare: Precizie ridicată

- Industrii aplicabile: ateliere de materiale de construcții, ateliere de reparații de mașini, fabrici de producție, lucrări de construcții, energie și minerit

- Showroom Location: Canada, United Kingdom, United States, France, Germany, Russia, Japan, Australia

- Tip de marketing: produs nou 2021

- Raport de testare a mașinilor: furnizat

- Inspecție video de ieșire: furnizat

- Garanția componentelor de bază: 3 ani

- Componente de bază: rulment, motor, pompă, angrenaj, PLC, recipient sub presiune, motor, cutie de viteze

- Sistem de control: Estun E21 NC Control

- Material de tăiere: metal, oțel inoxidabil, oțel carbon

- Servicii post-vânzare oferite: Piese de schimb gratuite, Instalare pe teren, punere în funcțiune și instruire, Servicii de întreținere și reparare pe teren, Asistență online, Suport tehnic video

- Service după garanție: Suport tehnic video, Asistență online, Piese de schimb, Serviciu de întreținere și reparații pe teren

- Local Service Location: Canada, United Kingdom, United States, France, Pakistan, Mexico, Russia, Australia, South Africa

- Certificare: CE